How To Fix Misaligned Serpentine Belt

The serpentine belt is responsible for transferring ability from the engine to the car's various components. Information technology is a heavy-duty chugalug with teeth to grip and bulldoze pulleys.

Some serpentine belts are fabricated with a stretchable fabric that makes them loose. This is considering they are designed to be loose on the engine and tight effectually the pulleys.

You might have to supervene upon your serpentine belt if it is too loose or tight. You should too check it for whatsoever visible impairment, such every bit cracks or fraying.

Many things tin can crusade a loose serpentine belt. The well-nigh mutual causes are that the belt has gone through too much habiliment and tear or has non been properly tightened.

If you lot observe that your serpentine belt is loose or non tight enough, this could be a sign that it needs to be replaced soon. Y'all should have information technology inspected by a mechanic every bit soon every bit possible earlier whatever more impairment can happen to your engine.

Why Is My New Serpentine Chugalug Loose?

A serpentine belt must be constantly tensioned to foreclose it from coming off. The belt tin can come off if the alignment is not aligned. It is possible that the tensioner is out of alignment and not applying enough tension to the belt.

You should accept a mechanic check the tensioner and supplant information technology if necessary. If in that location is a loose idler pulley or an out-of-aligning tensioner caster, information technology may be the cause.

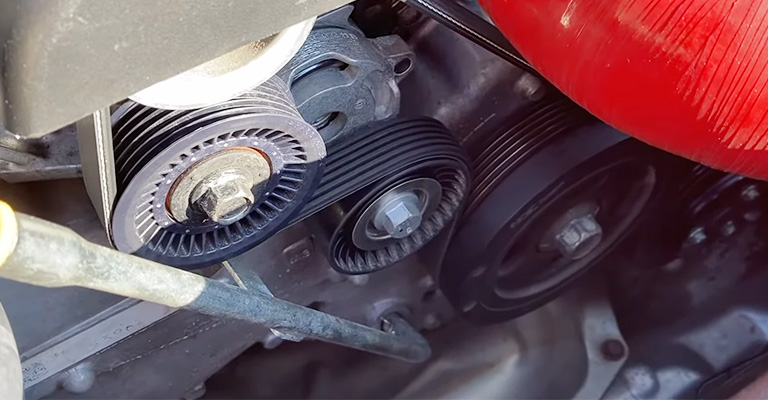

In a serpentine belt pattern, the tensioner pulley is used to adjust belt tension as needed by increasing or decreasing the tension on the belt. A loose tensioner pulley or a belt that has been out of adjustment could cause the belt to autumn off.

The Problems With Belts And Tensioners That Can Crusade Them To Suspension Or Produce Noises

Generally, alternator failure is acquired by the front and rear bearings that carry the armature; the belt is directly responsible for the bearings' health. Having a too tight chugalug will cause excessive side loads and cause the bearings to overheat.

Consequently, the alternator volition make noise, lose power, and even seize. The alternator will slip if the chugalug is also loose. Alternators and batteries may have to work harder due to this slipping. The following are some of the nearly common bug:

Wear And Tear On A Regular Ground

Serpentine belts with ribbed sides at present have soft felt-like surfaces. A cracked chugalug tin be seen in the photo below; as the belt rubber wears out, it hardens and cracks. Wearing out a belt causes it to stretch and lose tension.

From time to fourth dimension, the belt slips due to this. The engine might bleat or chirp under the hood during wet weather or when the engine is started in the forenoon.

Tensioner Bearings Or Idler Pulleys That Are Noisy

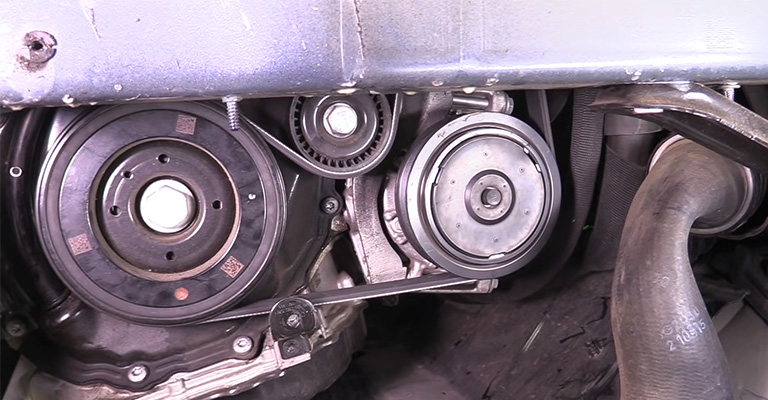

The photograph shows a costless-spinning caster used by many cars to route serpentine belts. Idler pulleys are used for this purpose. In that location is a small bearing that makes it a spin.

If the bearing wears out, information technology volition make a whining or whirring dissonance. Because many belt-driven devices tin make like noises, diagnosing this one may take some time.

The Chugalug Pulley Is Misaligned

There are several pulleys on which a serpentine chugalug runs. The chugalug will squeal if, for some reason, whatever belt-driven device or tensioner pulley is not aligned with it.

A new belt is often discovered squealing or wearing out fast after it has been replaced. The chugalug wears out more quickly on one side of the car, which is i of the symptoms of this problem.

There Is An Event With The Manual Chugalug Tension

In that location are some cars that permit the belt tension to be adjusted manually as it stretches over time. If the tension is not adjusted in time, the belt will skid.

In that location is probably zip more annoying than a car with an one-time Japanese or Korean engine that makes an awful screeching racket when it is started.

Hydraulic Belt Tensioner Problems

The tension is maintained by a little "shock absorber" in place of bound in many cars with hydraulic serpentine chugalug tensioners. In that location is also a possibility of failure.

If the engine runs, yous may hear a rattling noise from the belt surface area or a leak from the tensioner. In many cars, this item fails frequently.

Bad Spring-Loaded Automatic Belt Tensioner

Any chugalug needs to be tensioned correctly. Former spring-loaded automated chugalug tensioners often become weak due to seized-up or worn parts. Serpentine belts tend to slip without proper tension.

This will cause the belt to wearable out more quickly. The tensioner of a serpentine belt can seize up, causing the chugalug to autumn off.

When the steering wheel is turned to one side or the engine is started, a loose serpentine belt volition squeal loudly. Information technology is as well possible for a serpentine belt to go on slipping off the caster if the tensioner is not working correctly.

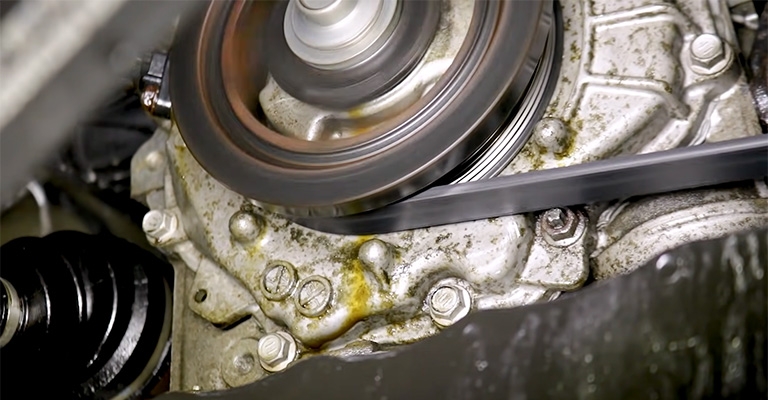

Oil Leaks

In some cases, an engine develops oil leaks around the belt expanse, soaking the belt in oil, as shown in the photo. There is a possibility that oil or coolant tin impairment the serpentine belt or timing belt very quickly.

An engine with an oil leak around the chugalug area had a new serpentine belt last less than a calendar week. The installation of a new belt would be pointless in this case. The kickoff thing that needs to exist washed is to ready the oil leak.

Problems with Serpentine Belts & How to Set Them

A misaligned serpentine chugalug or a defective tensioner is commonly the cause of serpentine belt vesture. A belt inspection can help you diagnose the problem- both before and after the belt is removed- even if you tin't hear the problem.

Fraying

A belt that frays at the edge is usually a sign that the pulleys are misaligned. An accessory drive caster side scrapes on the belt's pinnacle edge when information technology is not properly positioned on the pulley, somewhen fraying information technology.

In most cases, yous can discover this by observing the habiliment on the border of the chugalug. Pulleys and belts rub against each other, causing a thumping or rubbing audio.

Glazing

It is caused by the belt slipping, and the belt forms glazing on its edges, ridges, or grooves. At that place tin can be slipping due to a loss of belt tension (or a weak tensioner) or misalignment of the pulleys.

Whenever the belt slips off its track, friction between the belt and accessory drive pulleys leads to belt overheating. Squealing noises ordinarily point that it'due south fourth dimension to change your light bulb.

Excessive Cracking

A person'southward historic period is usually a contributing gene to excessive cracking. Rubber becomes drier and less pliable with age and apply, making serpentine belts more than prone to cracking equally they age.

A defective tensioner, however, tin as well crusade groovy. Keeping the belt tight on the pulleys is the tensioner'southward task, which is spring-loaded. A loose belt should always be checked to see if the tensioner is working properly or if it starts slipping.

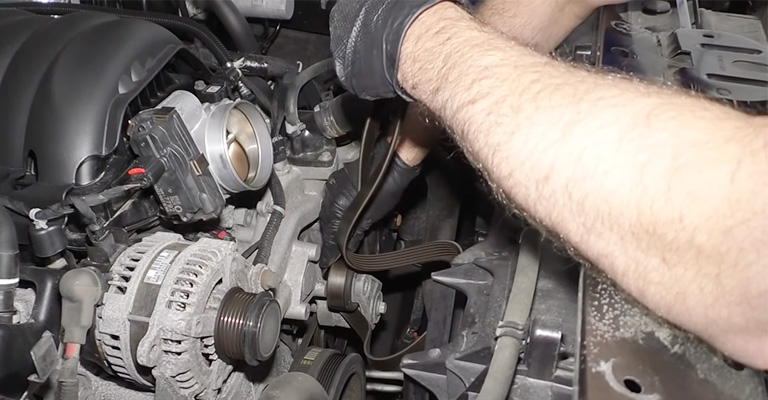

How to Tighten a Serpentine Belt?

Your alternator will non charge your battery properly if your serpentine belt is as well loose, and your accessories may also not piece of work properly. You should tighten your belt to ready this problem.

Pace 1

The serpentine belt tension tin can be adapted by opening the hood and locating the adjustment spiral. There is usually a wing nut on this spiral, located near the alternator.

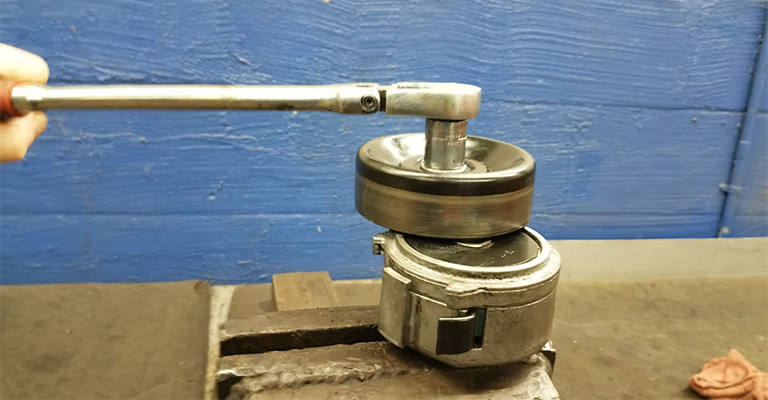

Stride 2

Apply tension past placing the socket end of the socket wrench over the wing-nut and turning clockwise. The wing nut volition most likely not be able to be adjusted by paw, so check your socket fix for a socket that will fit snugly over the nut and tighten it, thereby adding more tension to the serpentine belt.

Stride 3

Brand certain the chugalug is tensioned periodically. Grab any part of the belt between ii pulleys with your fingers. For most vehicles, the belt should have near one/iv inch of play.

Step 4

Make sure the belt tension is correct a second time. The chugalug should be examined in motility after the vehicle has been started. The alternator will whine if at that place is a whine coming from information technology.

An alternator that whines or pulses indicate that the chugalug tension is too tight, which damages the alternator. Recheck the tension by loosening the belt and turning the adjustment spiral counterclockwise.

Pace 5

Make sure everything is in lodge. All your accessories should exist able to provide continuous ability. Make sure all of your accessories are turned on at the same time. A chugalug that is not tensioned correctly will outcome in abnormalities.

What Happens If A Serpentine Chugalug Breaks?

An automobile that breaks its serpentine chugalug must be towed without existence able to drive. Unless a serpentine belt is installed, the engine will overheat if the water pump is non working.

If it breaks, other parts can be damaged as well equally the belt. In that location accept been cases where ripped belts have acquired broken radiator shrouds and ripped coolant hoses. An under-the-hood slapping, squealing, or knocking noise is a sign of a broken serpentine chugalug.

It is likewise possible that the bombardment-shaped alert low-cal on the charging system will illuminate because the alternator will cease charging the battery. A ability steering pump that relies on hydraulics will result in strong steering.

How Ofttimes Should Serpentine Belts Be Replaced?

The lifespan of a serpentine belt can range from 30,000 to more than 100,000 miles. Almost all car manufacturers recommend inspecting serpentine belts during regular maintenance rather than specifying intervals for serpentine belt replacement.

In addition to checking for cracks, splits, damaged edges, missing chunks, glazing, and other signs of wear, a mechanic will as well inspect your vehicle'due south oil.

When a chugalug is worn out, it'south piece of cake to tell. When a belt wears out, it needs to be replaced. Information technology is too necessary to supplant serpentine belts that have get soaked in oil or are stretched.

The Cost Of Replacing A Serpentine Belt

You must supplant both belts simultaneously if your motorcar has two belts, as this volition save you labor costs. In addition, serpentine belt replacement is a good idea before a long drive. The cost of replacing a serpentine belt range from $18 to $75 for the function and $50 to $150 for the labor.

Final Words

When your drive belt is loose, you lot may have trouble powering your vehicle's accessories, such every bit air-conditioning, power steering, or alternator, or you may even experience motor damage.

Most vehicles tin suit drive belt tension with simple hand tools, but some crave special tools to maintain proper tension.

Source: https://hondatheotherside.com/tightening-a-serpentine-belt/

0 Response to "How To Fix Misaligned Serpentine Belt"

Post a Comment